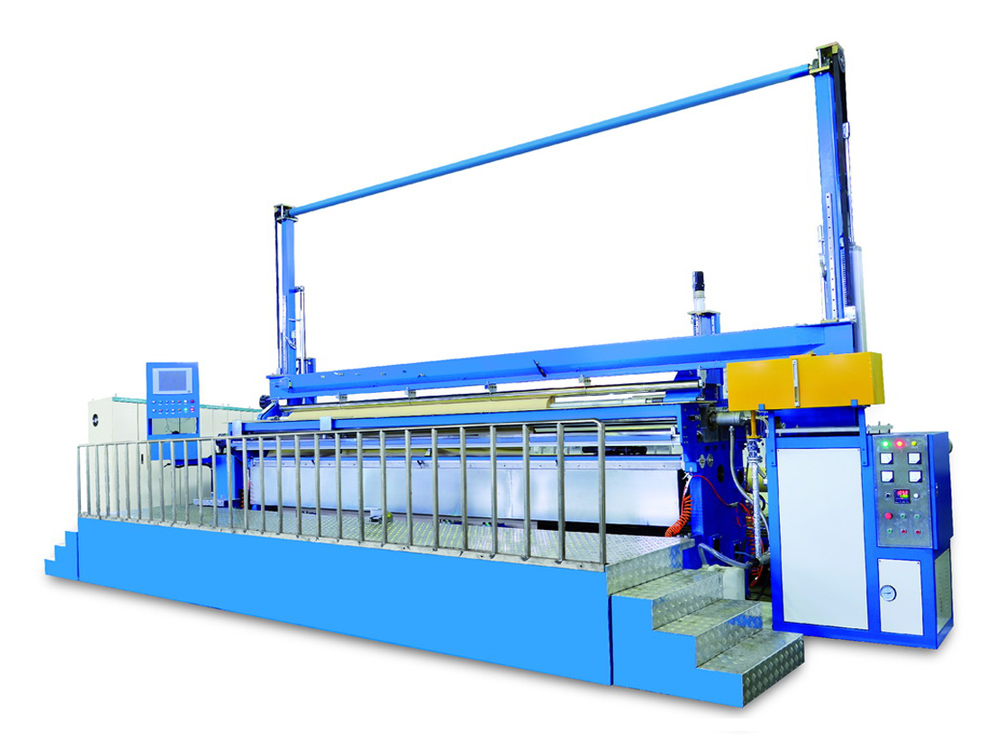

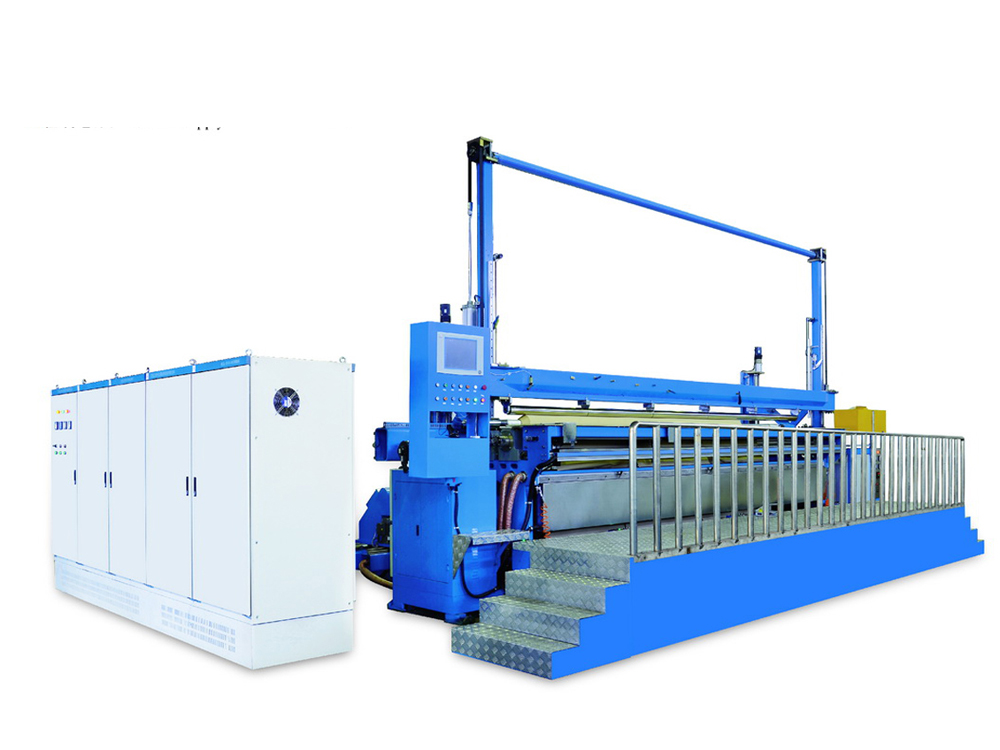

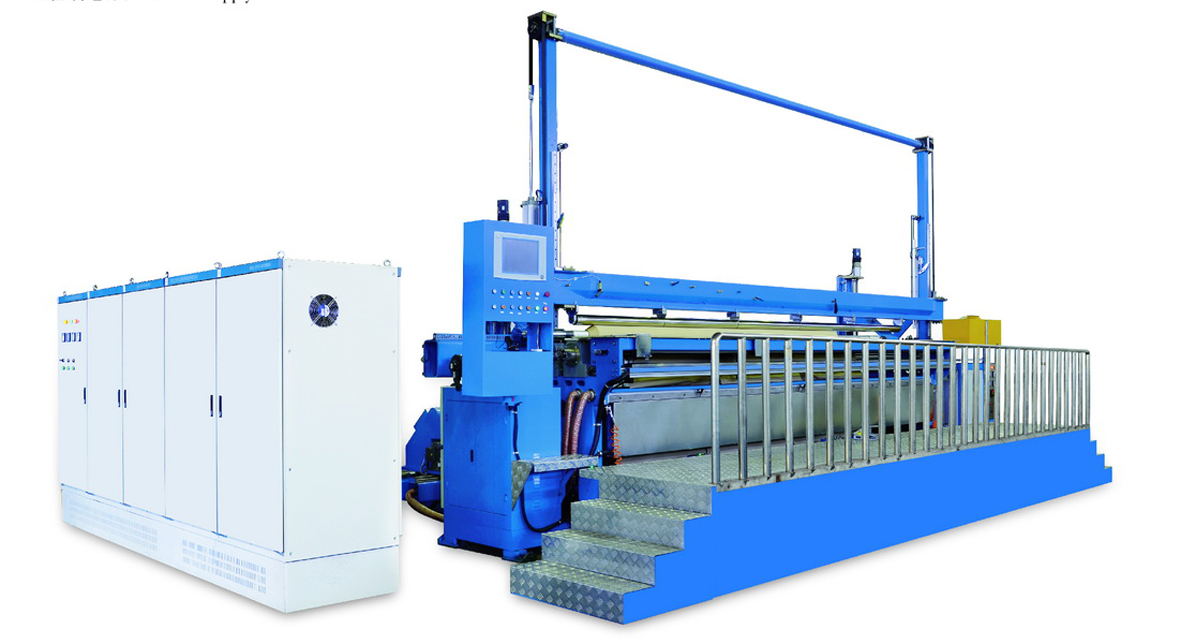

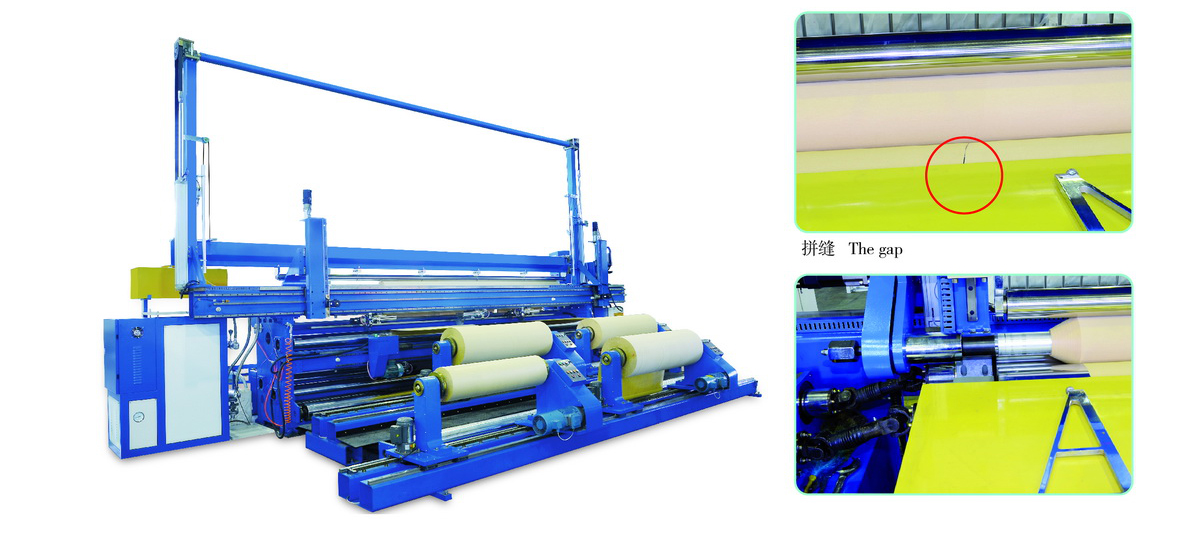

Product Description of Winding Machines For Condenser Bushings

Winding machines for condenser bushings is suitable for RIP and OIP combination capacitance bushing) of resin impregnated and oil impregnated paper. Up to 4 unwinders with whole width paper, automatic “S” shape winding.

Work Environment of Winding Machines For Condenser Bushings

1. Temperature of nature: 15℃-35℃

2. Relative humidity: ≤90%

3. Voltage: AC380V±10%, 50Hz

4. Control voltage: 24V

Technical Parameters of Winding Machines For Condenser Bushings

|

Tube inner diameter:

|

φ35-φ80mm

|

|

Tube outer diameter:

|

φ45-φ120mm

|

|

Tube length:

|

1800-6000mm

|

|

Length of bushing:

|

1500-5500mm

|

|

Diameter of final active part:

|

φ85-φ320mm

|

|

Winding speed:

|

0.1-10m/min

|

|

Accuracy of measuring diameter:

|

0.1mm

|

|

Height of operation:

|

≈1200mm(to the work table)

|

|

Width of each unwind:

|

4*1500mm, 3*2000mm, 3000+2000mm

|

|

Thickness of the paper:

|

Plate paper: 0.09-0.1mm

Crepe paper: 0.3-0.35mm

|

|

Inner core of the paper:

|

φ76mm,φ152mm

|

|

Diameter of the unwind paper:

|

≤800mm

|

|

Weight of each unwind:

|

Plate paper≤600kg/roll

Crepe paper≤400kg/roll

|

|

Numbers of the knives:

|

max 6 pcs

|

|

Width of foil:

|

150-1000mm

|

|

Length of foil:

|

300-5000mm

|

|

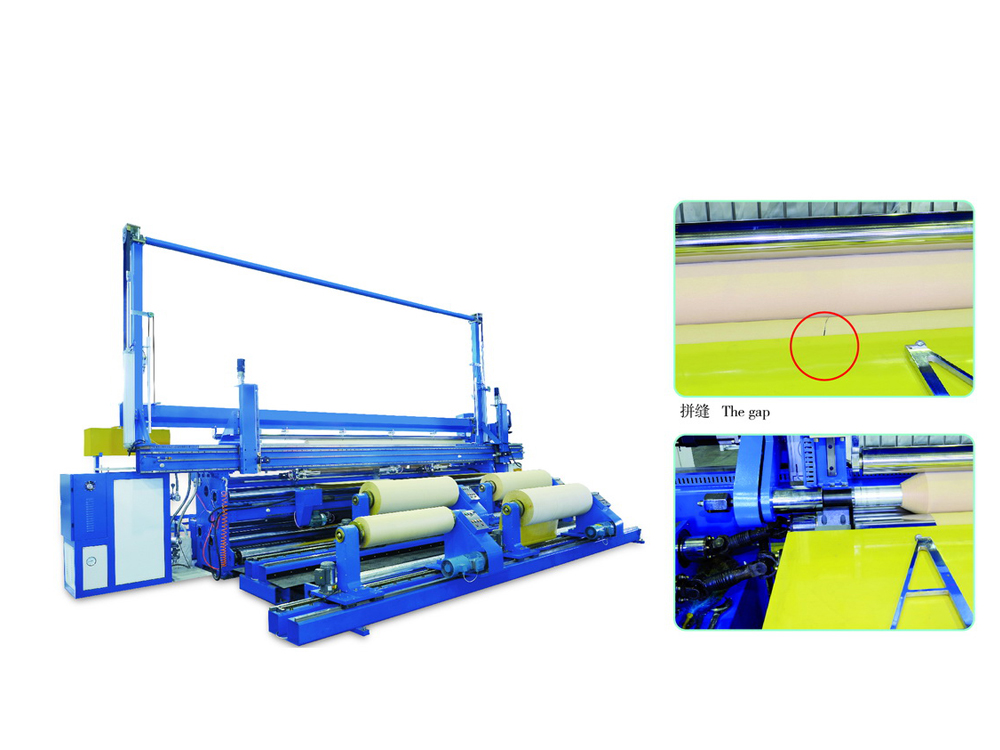

The gap:

|

≤3mm

|

|

Tension of the paper:

|

0-1000N/m (adjustable)

|

|

Tolerance of winding width:

|

±1mm

|

|

Tolerance of bushing ends:

|

≤1mm

|

|

Temperature of heating roll:

|

20-100℃

|

|

Temperature of Infrared rays:

|

40-100℃

|